Sie haben eine Produktidee?

Gerne begleiten wir Sie von Beginn an. Überzeugen Sie sich von unseren Leistungen und vertrauen Sie auf unsere langjährigen Erfahrung.

Im Anschluss an die Herstellung unserer Artikel sind wir in der Lage Montagearbeiten, Bedruckungen und diverse weitere Arbeiten selbst durch zuführen.

Following the production of our articles, we carry out various other work ourselves. Among other things, we have experience in the assembly and processing of high-quality electronic components, common connection techniques are a matter of course for us.

We would also like to develop further in this area, there are no limits for us, please contact us.

With our very well established network of logistics partners, we can guarantee fast and safe deliveries to your doorstep.

We have extensive experience in the production of components for the automotive industry. We manufacture parts for brands such as Audi, Porsche and VW. The main materials used for this are polyamides reinforced with glass fiber.

Our core competencies include specialization in glass-fiber reinforced plastics, which are used in the manufacture of complex, mechanically resilient technical components, for example in chassis, or as sealing components in washing machines and dishwashers.

We manufacture modules, covers and other parts for the electrical industry from materials such as ABS, PC and PP.

For the food industry, we manufacture various products from plastics suitable for food use, as well as from bioplastic solutions based on corn starch, for example.

Individual handling solutions for the packaging industry such as edge protectors or centering devices as packaging and transport protection are also part of our portfolio.

Everything from one source – we offer you individual product solutions also from several components, very gladly complete with subsequent assembly, accordingly adapted to your needs.

We would like to discover new industries together with you as our customers.

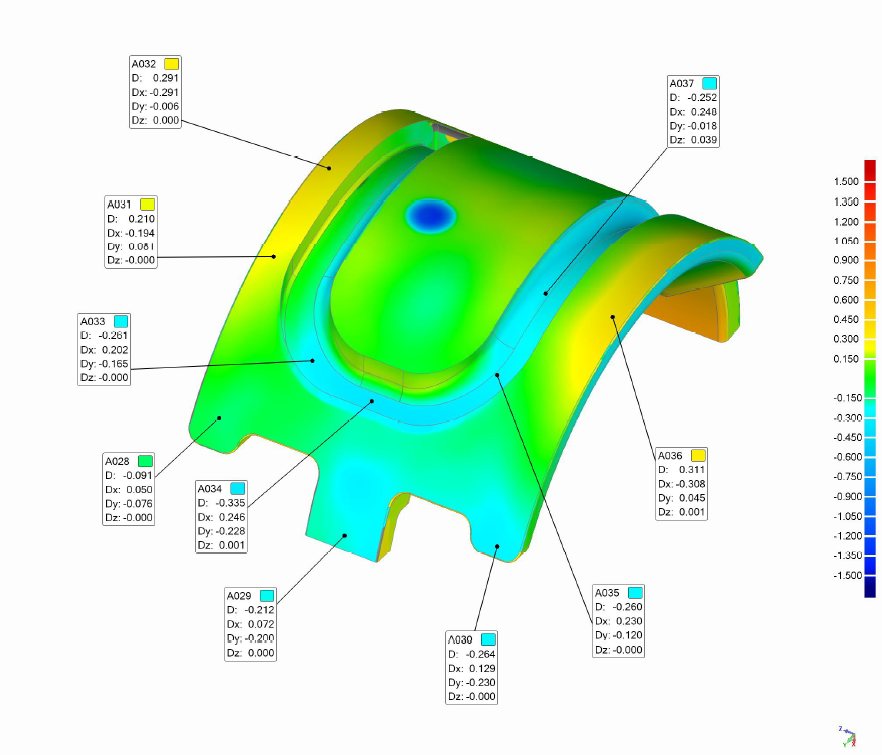

Many of our production parts are safety components for the automotive sector, which must meet the highest quality requirements. Our equipment offers, among other things, optical as well as ultrasonic measuring devices in order to be able to realize precise dimensional inspections. Individual batches of injection molded parts are comprehensively tested. The measured values of all individual parts are transferred to the QM documentation, and the process capability (CPK value) is checked across the entire production process on the basis of your limit values. We guarantee our customers and partners an objective assessment of our performance.

We are certified according to the current quality standard ISO 9001.

Do you have a specific product idea and would like to receive an individual offer from us in a quick and uncomplicated way? Use our direct inquiry form and we will get back to you.

Do you have a specific product idea and would like to receive an individual offer from us in a quick and uncomplicated way? Use our direct inquiry form and we will get back to you.

ul. gen. Wł. Sikorskiego 37

Managing Director

Product management

Quality management

Are you looking for new challenges for your professional career? Then you are very welcome at Thermoform. We look forward to meeting you and maybe you too will soon be a part of Thermoform!

The company Thermoform GmbH & Co KG was founded in May 2009 by Dieter Oestreich. Since then, the company has been producing and developing high quality plastic injection molded parts, especially for the automotive industry, for the packaging industry, as well as product solutions for other different industries.